If you want to control and automate a process, you first need detailed information about it. This task is performed by sensors covering a wide range of sensing principles, and also involves reading 1-D and 2-D codes for identifying and detecting parts, workpieces, and means of transport. Camera-based code readers have proven their worth in this domain, which can be adapted very flexibly to suit different tasks. The new VOS-I series code readers show what the top range of this technology can do.

The requirements for reading barcodes, Data Matrix codes, QR codes, etc. in factory automation are much higher than just scanning packaging at the supermarket checkout. Reading codes under industrial conditions is a real-time task that is integrated into automated, quick production, processing, and transportation processes. Speed and reliability are the top priority.

Solutions for Multiple Applications Covered by Numerous Functions

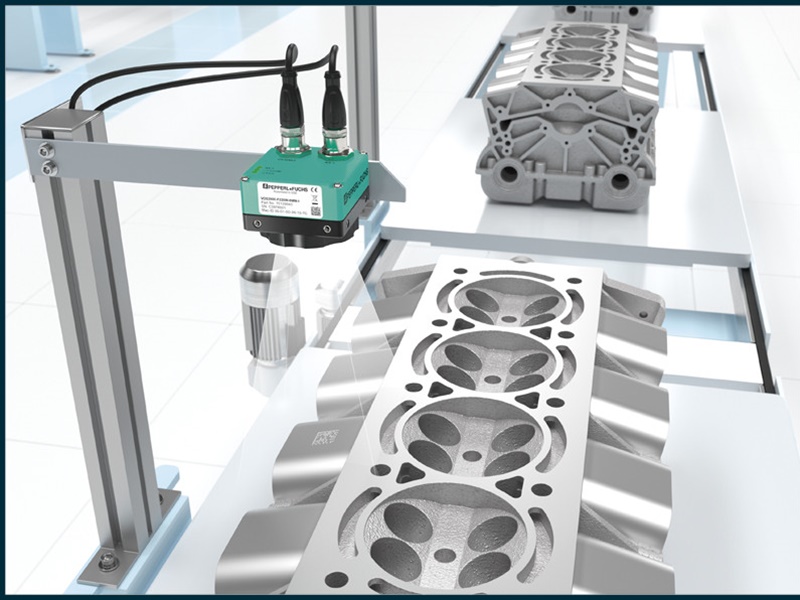

Securely reading all common 1-D and 2-D codes including DPM codes is the core functionality of the VOS-I series universal code reader from Pepperl+Fuchs. The fixed-installation vision sensors support large distance and sensing ranges, read codes on objects that move at speeds up to 4 m/s, and read very small codes.

The readers also offer a multitude of intelligent functions that allow users to carry out all conceivable reading tasks. These functions include match code, multi-window and multi-code readings, output string formatting via scripts, and the ability to group together several VOS-I devices.

All device versions have a LAN connection for PROFINET IO, EtherNet/IP, Ethernet TCP/IP, a serial RS232 interface, and three freely configurable digital inputs/outputs for integrating the code readers seamlessly into existing control and networking systems.

The new code readers are typically used in applications in the automotive industry, in the production of electronic assemblies, and in the logistics sector. DPM (Direct Part Marking) codes are often used in the automotive industry. Mechanical needles and laser light burning techniques are used to apply these codes to the metal surfaces of parts such as engine blocks.

Reading a thinly needle-punched code can sometimes be difficult, so developers have created a special decoder for this application. It is supplemented by an electronic filter bank that prepares raw images to suit the needs of the user and enable reliable reading in the future. This type of filter ensures that these thinly needle-punched modules are enlarged before the actual evaluation.

With additional external lighting, the VOS-I is even able to reliably read difficult DPM codes up to two meters away.

Small Codes with a Module Size of 0.1 mm

When manufacturing and equipping printed circuit boards in the electronics industry, very small codes need to be detected, possibly from several printed circuit boards at the same time. Since there is usually limited space on printed circuit boards, very small lasered Data Matrix codes are often used in these applications.

The VOS-I can decode Data Matrix codes with module sizes of only 0.1 mm and can perform multi-code readings. This allows up to 64 codes to be read at the same time in a single reading window or even more codes if several reading windows are used. The vision sensor can even read different code types simultaneously, so mixing different code symbologies in the same application does not pose any issues.

Multi-code readings are also often required in logistics, such as when detecting Odettes. Data is distributed over a number of different codes in the labels used for standardised information exchange when delivering goods.

VOS-I code readers feature another interesting functionality that proves advantageous in logistics applications. Boxes and packages are often strung in a random order on conveyor belts and the codes may be on any side. To capture all of the packaging codes simultaneously, multiple VOS-I code readers can be logically interconnected.

One of the devices acts as the main device, which collects the read results of the network, and works with the other devices to transmit this data to the higher-level plant control system.

Evaluation of Code Quality Based on ISO Criteria

The new code readers from Pepperl+Fuchs have a code quality output based on the original criteria set out by the ISO. The output is only “based on” the criteria because there is no ISO standardised lighting in productive operation. It should be noted that the quality output also applies to DPM codes, as per ISO/IEC TR 29158, which is especially relevant to DPM codes.

Powerful script functionality allows the collected data to be processed according to user requirements, processed further, and assigned to specific outputs. Together with the output string formatting, data—including that from multi-code readings—can be broken down into substrings, reassembled differently, and therefore perfectly adapted to the field formats and structures of ERP systems.

The “match code” function is often used in industrial processes. This involves the code reader comparing the currently read value with a previously taught-in reference value or a reference value specified by the control panel. The output only has to indicate whether the values are a “match” or “no match.”

If the product is changed, the new reference value can be taught in by setting a hardware input on the fly. The next read value is adopted as the new reference value. Several match codes can also be stored in the code reader’s memory and used as reference when comparing values.

Emulator for Offline Optimisation

The VOS-I can store captured images in the sensor or on an FTP server. These can be analysed using an emulator to determine the ideal sensor settings for the relevant boundary conditions. Multiple images or entire image sequences can be evaluated as part of the optimizations. The result is a rugged and reliable code reading that the user can take in their plant.

The VOS-I stores up to 32 jobs, which can be activated remotely via the fieldbus. Versions of the code readers with different fixed focal lengths and different resolutions up to 5.2 mega pixels are available. Furthermore, the lens and lighting of C-mount versions allow the code readers to be precisely adapted to any special features of the application.

Pepperl+Fuchs

Tel. +27 10 430 0250

info@za.pepperl-fuchs.com

www.pepperl-fuchs.com